Lithium-ion Battery Protection Circuit Module (PCM): Importance, Safety, and How It Works

Have you ever wondered what keeps your electric vehicle (EV) battery from overheating, short-circuiting, or getting damaged during charging? The answer lies in a small but mighty component called the Protective Circuit Module (PCM).

As a veteran in the field of battery design and EV technology, I’ve seen firsthand how crucial this little board is. It’s the silent guardian, the unsung hero working tirelessly to ensure the safety, longevity, and performance of your EV’s most expensive component—the battery pack.

In this article, we’ll dive deep into the world of PCMs. We’ll explore what they are, how they work, and why they are essential for every EV. Whether you’re an EV owner, an engineer, or just curious about what makes these incredible machines tick, you’ll gain a new appreciation for the technology that keeps us all safe on the road.

What Exactly is a Protective Circuit Module (PCM)?

Think of a PCM as the brain and security guard for a battery cell or pack. Its primary job is to monitor and protect the battery from a range of dangerous conditions. These conditions can damage the cells, reduce their lifespan, or even cause a fire.

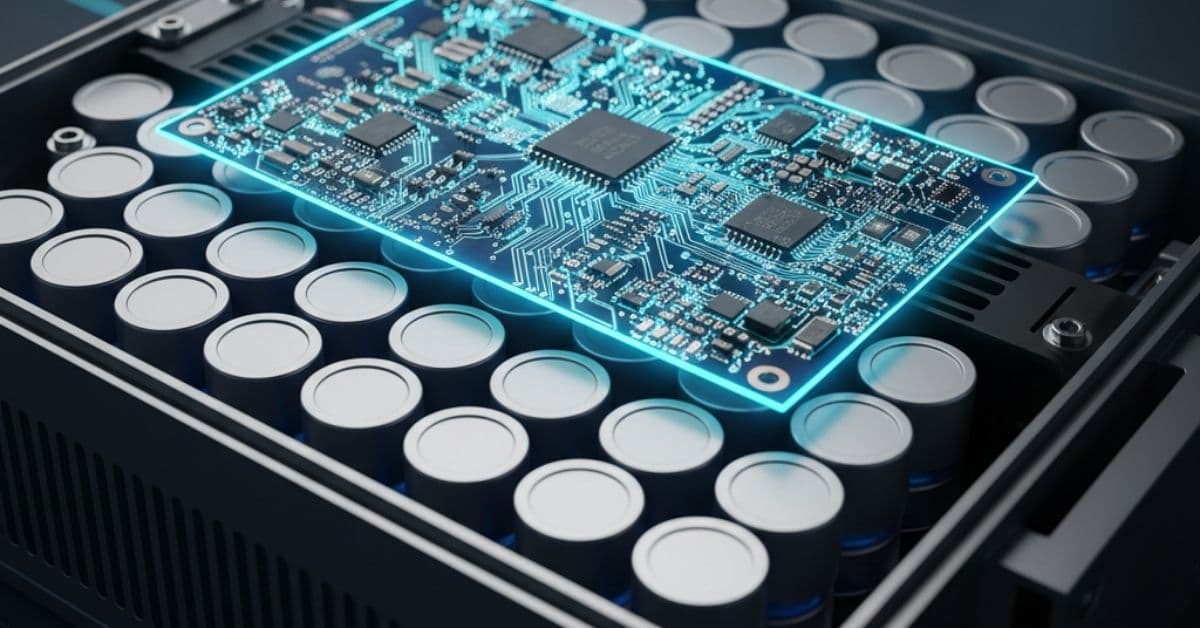

A typical PCM is a small electronic circuit board that’s directly connected to the battery. It’s often integrated into the battery management system (BMS) of an EV, which is the complete “brain” of the battery pack. While the BMS handles higher-level functions like State of Charge (SoC) and cell balancing, the PCM focuses on the immediate, physical protection of the individual cells.

Core Functions of a PCM:

- Overcharge Protection: Prevents the battery from being charged beyond its safe voltage limit.

- Over-discharge Protection: Stops the battery from being drained too low, which can cause irreversible damage.

- Overcurrent Protection: Shuts off the circuit if the current flow becomes too high, protecting against short circuits.

- Short-Circuit Protection: An immediate, fast-acting defense that cuts power instantly in the event of a short.

Without a PCM, an EV battery would be a ticking time bomb. The rapid flow of energy during charging or discharging could easily push the cells past their limits, leading to catastrophic failure.

The Big Three: How PCMs Protect Your Battery

Let’s break down the three main threats a PCM protects against. Understanding these threats helps to appreciate the complexity and importance of this little circuit.

Overcharge: The Silent Killer

Charging an EV battery is a precise process. Each cell has a specific voltage limit it can handle. For a typical Lithium-ion cell, this limit is around 4.2 volts. Pushing a cell past this point, even slightly, can cause serious problems.

When a cell is overcharged, it undergoes a process called lithium plating. This is where metallic lithium forms on the anode, a key part of the battery. This plating is dangerous because it can puncture the separator (a thin layer that keeps the anode and cathode apart), leading to an internal short circuit.

A PCM constantly monitors the voltage of each cell. If it detects a cell’s voltage creeping towards the danger zone, it triggers a charge cut-off. This immediately stops the flow of electricity to that cell or the entire pack, preventing overcharge and protecting the battery from irreversible damage.

Over-discharge: Draining the Life Away

Just as overcharging is bad, so is over-discharging. Draining a Lithium-ion cell too low (below around 2.5 volts) can also cause irreversible damage.

When a cell is over-discharged, the internal structure of the cathode can be destroyed. This means the cell’s ability to store and release energy is permanently reduced. It’s like draining a sponge so dry it can no longer absorb water effectively.

A PCM is programmed with a minimum safe voltage. When a cell’s voltage drops below this threshold, the PCM activates a discharge cut-off. This stops the battery from powering the car, even if you try to press the accelerator. This is why when your EV battery “dies,” it’s not truly empty; the PCM has simply intervened to protect it.

Overcurrent & Short Circuits: The Sudden Threat

This is the most dramatic and dangerous of the three threats. An overcurrent event happens when too much power is pulled from the battery too quickly. A short circuit is an extreme version of this, where electricity finds a low-resistance path, bypassing the normal circuit. This can happen due to a physical short, like a damaged wire, or a fault inside the battery itself.

An overcurrent can generate intense heat, potentially leading to a fire. A short circuit can be even more dangerous, causing an immediate, massive release of energy.

A PCM’s protection against this is rapid and decisive. It includes a current sensor that monitors the flow of electricity. If the current exceeds a predetermined safe limit, the PCM opens a switch, instantly cutting the power. This is much faster than a traditional fuse and is crucial for preventing a thermal runaway event.

A Case Study: The Difference a PCM Makes

I once consulted on a project where a client was developing a custom EV battery pack. To save on costs, they decided to use a basic battery pack without a sophisticated PCM or BMS. They relied on simple fuses and circuit breakers.

During testing, a minor wiring fault caused a short circuit. Because there was no fast-acting PCM, the fuses couldn’t react quickly enough. The short circuit generated immense heat, and within seconds, several cells in the pack began to overheat, leading to a thermal runaway. The result was a destroyed battery pack and a very real fire hazard.

This experience drove home a critical lesson: cutting corners on safety components like PCMs is never worth the risk. Modern EV manufacturers understand this. They invest heavily in sophisticated BMS and PCM technology, not just for performance, but for the fundamental safety of the vehicle and its occupants.

How PCMs Fit into the Bigger Picture: The BMS

A PCM is often a key component of a larger Battery Management System (BMS). While the PCM focuses on direct, physical protection of the battery cells, the BMS performs a much wider range of functions.

| Feature | Protective Circuit Module (PCM) | Battery Management System (BMS) |

|---|---|---|

| Primary Role | Direct, physical protection of cells | Overall management of the entire battery pack |

| Key Functions | Overcharge, over-discharge, overcurrent, short-circuit protection | Cell balancing, SoC calculation, SOH estimation, thermal management, ECU communication |

| Level of Operation | Cell or module level | Pack level |

| Example Component | A small circuit board with a few ICs and MOSFETs | Overcharge, over-discharge, overcurrent, and short-circuit protection |

PCM vs. BMS – A Quick Comparison

In a typical EV battery pack, there will be multiple PCMs (one for each group of cells or module) that all report to a central BMS. This layered approach ensures redundancy and provides a robust safety net.

The Technology Inside: What Makes a PCM Work?

So, what’s inside this little board? A typical PCM contains several key components that work together to provide protection.

- Sensing Circuit: This part of the PCM constantly monitors the voltage of each cell. It’s highly accurate, as even a small deviation can signal a problem.

- Current Sensor (Sense Resistor): A small resistor is placed in the circuit. The PCM measures the voltage drop across this resistor to calculate the current flowing through it.

- Protection IC (Integrated Circuit): This is the “brain” of the PCM. It’s a small chip programmed with the safe voltage and current limits. When the sensing circuits detect a value that’s out of range, this IC triggers the protection mechanism.

- MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors): These are the electronic switches that the Protection IC controls. When a dangerous condition is detected, the IC sends a signal to the MOSFETs, causing them to open the circuit and stop the flow of electricity.

The speed at which these components operate is critical. For example, a short-circuit protection circuit must react in microseconds to prevent damage. This is a testament to the sophisticated engineering that goes into these modules.

Practical Tips for EV Owners

As an EV owner, you don’t need to be an expert in PCM design, but understanding its role can help you practice good battery habits.

- Avoid Extreme Charging/Discharging: While your PCM will protect you, constantly pushing the limits (e.g., regularly charging to 100% or letting the battery drop to 0%) can put unnecessary stress on the cells over time.

- Don’t Mess with the Battery: Never attempt to open your EV battery pack or modify its internal components. The high voltage and intricate safety systems are not something to tinker with.

- Use Reputable Chargers: Always use the charger recommended by the manufacturer. Third-party chargers may not have the necessary safety features or may not communicate properly with your car’s BMS, potentially bypassing the PCM’s protections.

These simple practices can extend the life of your battery and ensure the safety systems, like the PCM, are not overworked.

FAQs

Q: Can a PCM fail?

A: Yes, like any electronic component, a PCM can fail. However, they are designed with a high degree of reliability and often have built-in redundancy. A failed PCM can either fail-safe (cut off power) or, in rare cases, fail in a way that allows a dangerous condition. This is why reputable manufacturers use high-quality components and rigorous testing.

Q: Is a PCM the same as a BMS?

A: No, they are not the same, but they are closely related. Think of the PCM as a component within the larger BMS. The PCM is focused on the direct, low-level protection of the cells, while the BMS handles the higher-level management of the entire battery pack.

Q: Do all EV batteries have a PCM?

A: Yes. Any modern EV battery, and in fact, most consumer electronics with a Lithium-ion battery (like your smartphone or laptop), will have a form of PCM. It is a mandatory safety requirement due to the inherent risks of lithium battery chemistry.

Q: How do I know if my PCM is working?

A: You typically don’t. The PCM works in the background and is transparent to the user. The best way to know if your battery’s safety systems are working is to ensure the car is well-maintained and to look out for any unusual warning lights or behaviors.

Conclusion

The Protective Circuit Module (PCM) is a perfect example of a small, often unseen component that plays a monumental role. It’s the silent guardian protecting your EV’s most valuable asset from common but dangerous threats.

The next time you plug in your EV, take a moment to appreciate the sophisticated engineering that goes into keeping you safe. The seamless charging and discharging, the long battery life, and the peace of mind you get on the road—it’s all thanks to the unsung hero, the PCM.