How Much Does A Solid State Battery Cost?

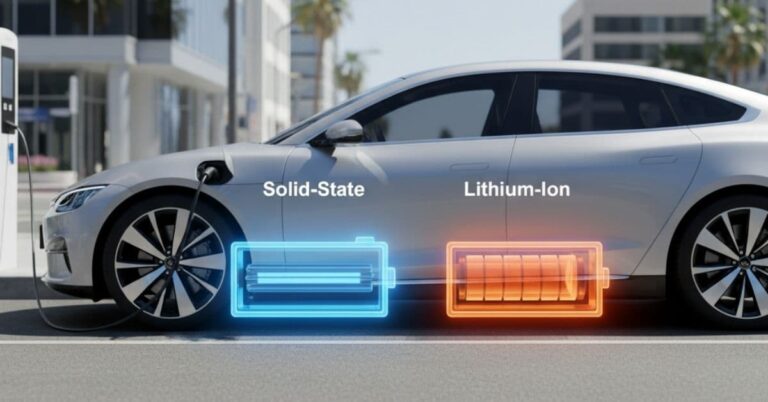

People have discussed the creation of solid-state batteries extensively recently. Compared to standard lithium-ion batteries, solid-state batteries can increase energy storage. They can also extend the life cycle of devices and improve their safety.

However, one major question remains: How much do solid-state batteries cost?

Current Cost Of Solid-State Batteries

Solid-state batteries are still under development, and companies do not sell them widely to the public. However, early market predictions show that solid-state battery prices are much greater than lithium-ion battery prices. Currently, companies price solid-state batteries between $100 and $300 per kilowatt hour.

To understand the difference, we must examine lithium-ion battery costs. Companies typically price lithium-ion batteries between $100 and $150 per kilowatt (kWh) in the market. The price comparison indicates that solid-state batteries are, on average, two to three times more expensive than similar lithium-ion batteries.

We see a significant price difference between the two battery types; however, we must consider the existing high cost of current lithium-ion battery technology. With increased research, greater development, and higher consumer demand, solid-state batteries will achieve competitive prices in the future.

The Future Of Solid-State Battery Costs

Solid-state battery technology improvements allow manufacturers to reduce expenses. Experts predict that within 10 years, solid-state battery prices will decrease considerably. The price drop will open up markets and potentially create major changes in technology usage. Electric vehicles, new personal electronic devices, and renewable energy storage systems may all experience changes. Currently, solid-state battery technology remains quite costly. However, ongoing research and development will increase the availability of technology, which will attract potential customers.

Factors Influencing The Cost Of Solid-State Batteries

Here are some reasons why solid-state batteries are more costly:

1. Materials Used in Solid Electrolytes

Manufacturers use materials like lithium phosphorus oxynitride or sulfide-based electrolytes for solid-state battery electrolytes. Those materials are less cheap and less easily found than those used for liquid electrolytes. Other solid-state electrolytes, including those used in lithium-ion batteries, also have higher costs. Therefore, the cost of solid-state batteries increases.

2. Manufacturing Complexity

Building solid-state batteries involves a much more complex process than building lithium-ion batteries. Producing solid-state batteries requires specialized tools and unique procedures to create solid electrolytes, which increases production costs.

3. Limited Production Capacity

Companies that produce solid-state batteries are still researching the subject and developing plans for large-scale manufacturing and sales. The limited demand for solid-state batteries makes production inefficient, raising customer costs.

4. Research and Development Costs

Companies and research groups spend a lot of money on research and development for solid-state battery technology. Investing in solid-state technology research and development resources is the most costly part of making solid-state batteries. The expenses increase significantly because companies and research groups increase their spending on solid-state battery research and development. Companies often transfer these high costs to the people who buy the batteries. As solid-state batteries become more available for sale, the expenses related to research and development will continue to push forward solid-state technologies, which will balance out the high prices.

What brand is the solid-state battery?

Many companies are working on solid-state battery development. Some major investors include:

- Toyota – Plans to launch solid-state EV batteries by 2027.

- Samsung – Researching safer and longer-lasting designs.

- QuantumScape – Aiming for commercial production by 2025.

- Solid Power – Partnering with Ford and BMW.

Who Is Winning The Battery Race?

Companies and nations are engaged in a real competition to improve their methods for storing energy. New developments in battery technology are appearing. We will examine the main competitors, the specific technologies, and the important parts of this intense contest. We want to understand who is winning the race to improve battery technologies.

Current Leader: Lithium-Ion Batteries

People consider lithium-ion batteries the most environmentally friendly battery type today. These batteries power 90% of electric vehicles, smartphones, laptops, and other devices. Major companies, including China’s CATL, Japan’s Panasonic, and South Korea’s LG Energy Solution, control the production of lithium-ion batteries. Tesla’s Gigafactories improve the production of lithium-ion batteries through optimization. The relatively low price, between one hundred and one hundred fifty pounds per kilowatt-hour, and the superior performance of these batteries secure their dominant position in the market.

Rising Challenger: Solid-State Batteries

Solid-state batteries promise excellent safety and increased energy storage. Toyota, Samsung, and QuantumScape have invested in solid-state battery technology. These companies cannot currently produce solid-state batteries in large quantities. The slow adoption of solid-state batteries results from high costs, ranging from £800 to £1500 per kilowatt-hour, and manufacturing challenges. Prototype solid-state batteries aim for deployment in electric vehicles between 2025 and 2030.

- Asia: China controls lithium mining and lithium-ion production. Japan and South Korea pioneer solid-state R&D.

- North America: Tesla and QuantumScape push lithium-ion upgrades and solid-state breakthroughs.

- Europe: BMW, Volkswagen, and Northvolt focus on sustainable lithium-ion and solid-state partnerships.

Critical Factors in the Race

- Energy Density: Solid-state leads (2x lithium-ion), but lithium-ion improves with silicon anodes.

- Safety: Solid-state avoids flammable liquids, reducing fire risks.

- Cost: Lithium-ion wins. Solid-state needs 5–10x price drops to compete.

- Charging Speed: Both aim for 15-minute EV charges. Solid-state has structural advantages.

- Sustainability: Lithium-ion recycling grows. Solid-state faces new material challenges.

Conclusion

Solid-state batteries provide more excellent energy storage and enhanced safety than lithium-ion batteries, but solid-state batteries cost two to three times more. We see the price of solid-state batteries from 200 to 300$ per kilowatt-hour, while lithium-ion batteries range from 100 to 150$ per kilowatt-hour. High material expenses, complicated manufacturing processes, and small-scale production contribute to the elevated prices of solid-state batteries.

Toyota, Samsung, and QuantumScape are the leading companies in solid-state battery development. These companies aim to introduce solid-state batteries into electric vehicles between 2025 and 2030.

Although lithium-ion batteries currently dominate the market, solid-state technology can potentially transform markets if companies successfully reduce costs. The battery competition relies on increasing production volume and decreasing research and development expenditures. We expect future solid-state battery prices to decline, reshaping the landscape of electric vehicles, portable devices, and renewable energy storage systems.

FAQs

How much do solid-state batteries cost today?

100–300 per kWh, 2–3x pricier than lithium-ion (100

–100–150/kWh).

Why are solid-state batteries more expensive?

Costly materials (e.g., sulfide electrolytes), complex manufacturing, and limited production scale raise prices.

Which companies make solid-state batteries?

Toyota, Samsung, QuantumScape, and Solid Power lead development, targeting EVs by 2025–2030.

What industries will benefit most from solid-state batteries?

EVs, renewable energy storage, and aerospace due to higher energy density and safety.