Are you curious about next-generation energy storage? Making a solid-state battery requires swapping flammable liquid electrolytes for solid alternatives, such as sulfides or polymers. This change offers a significant advantage: improved energy density in batteries and enhanced safety. The solid-state battery manufacturing process involves preparing lithium anodes, mixing cathode materials, and pressing these layers tightly.

Follow these steps to build your own solid-state battery prototype that offers much higher performance than conventional lithium-ion vs solid-state battery technologies.

Detailed Guide: Solid-State vs. Lithium-Ion Batteries

What materials are needed for solid-state batteries?

Before diving into the solid-state battery construction process, you must understand the essential parts. Unlike a standard battery, every component here is solid, making the interfaces critical.

Here are the key solid-state battery materials you will need:

- Solid Electrolytes: The backbone of the system. These can be ceramic electrolytes in batteries (like LLZO), polymer (flexible), or sulfide-based glass materials.

- Anode Material: Usually lithium metal or lithium alloy. This provides the highest possible energy density improvement in batteries.

- Cathode Material: The active electrode compounds, such as lithium cobalt oxide (LiCoO2), lithium iron phosphate (LiFePO4), or nickel-rich compounds (NMC).

- Binder: A substance (often a polymer) to hold the dry electrode materials together and bind them to the current collectors.

- Substrate Material: Thin metal foils—copper for the anode side and aluminum for the cathode side—that act as current collectors.

- Specialized Equipment: A glove box with an inert atmosphere (to handle reactive lithium safely) and a pressure mold (to form the battery layers).

Solid State Battery Manufacturing Process

Step 1: Choose The Right Materials

Selecting the right solid-state battery materials is the most crucial choice in the solid-state battery manufacturing process. The chosen materials need to be perfectly compatible to ensure the battery works well and lasts a long time.

a. Anode Material

Manufacturers commonly use lithium, silicon, or various lithium mixtures for the anode within batteries. Silicon offers the possibility of increasing the anode’s storage ability, but it increases in size during the charging process, and the expansion creates problems. Lithium remains stable, and manufacturers find it easier to use as a single material.

b. Cathode Material

The cathodes are active electrodes of compounds like lithium cobalt oxide (LiCoO2) or lithium iron phosphate (LiFePO4). These compounds can be charged and store energy.

c. Solid Electrolyte vs Liquid Electrolyte

This choice defines the battery. Solid-state batteries rely heavily on solid electrolytes to enable the flow of ions while guaranteeing the safety advantages of solid-state batteries.

- Companies primarily use lithium garnet, sulfide-based glass, and ceramic electrolytes in batteries.

- These materials facilitate the movement of ions between the anode and the cathode and prevent dangerous short circuits within the battery.

- The proper selection of solid electrolytes is crucial for the safety and efficiency of next-generation battery technology, especially when aiming for a quick charge rate.

“The solid electrolyte must be both an ionic freeway and an electronic insulator,” says Dr. John Goodenough, Nobel Laureate and pioneer of the Li-ion battery, highlighting the dual challenge in solid-state battery design.

Step 2: Create The Anode And Cathode Layers

After choosing the materials, engineers begin to make a solid-state battery by preparing the electrode layers. This process is complex because every layer must be thin, uniform, and defect-free.

Prepare the Electrodes Slurry

The key is creating a high-quality slurry.

- We mix the binding agent and a dissolving liquid with the positive or negative battery anode and cathode materials.

- Continue mixing until the mixture forms a thick, wet slurry, similar to pancake batter.

- We then use precision coating machines (like slot-die coaters) to apply the thick, wet mixture onto a slim metal sheet (copper for the anode, aluminum for the cathode).

Dry and Compress the Layers

The next steps are critical for performance and removing solvents.

- Compress the Layers: The layers are then sent through calendering rollers. This process, where the layers are squeezed between heavy rollers, makes the electrode dense and ensures good contact with the current collector. This densification is part of the solid-state battery manufacturing process that dictates the cell’s final energy density improvement in batteries.

2. Dry the Layers: After coating, the slurry must be thoroughly dried, often in a vacuum oven, to ensure that no solvent is left. The active material must adhere well to the foil.

Step 3: Solid Electrolyte Preparation and Film Forming

After preparing the electrodes, the solid-state electrolyte preparation must be completed. This is often the most technologically challenging part of solid-state battery construction.

a. Preparation Techniques

The preparation process is complicated because the solid electrolyte must maintain a consistent, ultra-thin thickness, be light, and be able to conduct ions strongly.

- Ceramics/Sulfides: The specific mixing process depends on the solid electrolyte type, which is ceramic or sulfide-based. Some, like polymers, are more straightforward because manufacturers can create them at low temperatures. However, highly conductive ceramic and sulfide electrolytes require very high temperatures (sintering) to form their final, dense shape.

- The Thin-Film Method: For highly advanced cells, engineers use sputtering or chemical vapor deposition to grow an extremely thin, perfect layer of the electrolyte directly onto one of the electrodes. This creates a thin-film solid-state battery that is ideal for small electronics.

b. Forming a Thin, Uniform Film

The electrolyte’s quality is vital because it affects the battery’s efficiency. A solid electrolyte that’s too thick or uneven can limit ion flow and reduce battery performance, increasing internal resistance.

- We must transform the electrolyte into a thin, uniform layer, often using tape casting or sputtering methods.

- The goal is to place a thin, flexible, or rigid solid electrolyte layer between the positive and negative electrodes.

- The electrolyte’s quality is vital because it affects the battery’s efficiency. A solid electrolyte that’s too thick or uneven can limit ion flow and reduce battery performance, increasing internal resistance.

Case Study

The biggest barrier to widespread adoption is how solid-state batteries are made cheaply and in large volumes. Toyota, a leader in SSB patents, has championed sulfide-based solid electrolytes.

The Challenge

Sulfide electrolytes have top-tier ionic conductivity, but they are extremely sensitive to moisture and must be handled in multi-million dollar, hermetically sealed, argon-filled glove box systems. This adds huge cost and complexity to the solid-state battery manufacturing process.

The Solution

Toyota and other partners have invested heavily in developing specialized roll-to-roll processing for these sensitive materials. They are focused on creating a continuous production line that maintains the inert atmosphere throughout, drastically improving manufacturing scalability and cutting down the cost compared to batch processing. This effort demonstrates that the key to mass market solid-state battery design lies in factory engineering, not just material science.

Step 4: Assemble the Solid-State Battery

This is the lamination stage where the magic happens—combining the solid components into a functional power cell.

The Layering and Sealing Process

1. Layer Stacking: People begin the solid-state battery construction by positioning the anode (lithium-metal foil) against one side of the solid electrolyte. Afterward, they place the cathode on the opposite side of the electrolyte.

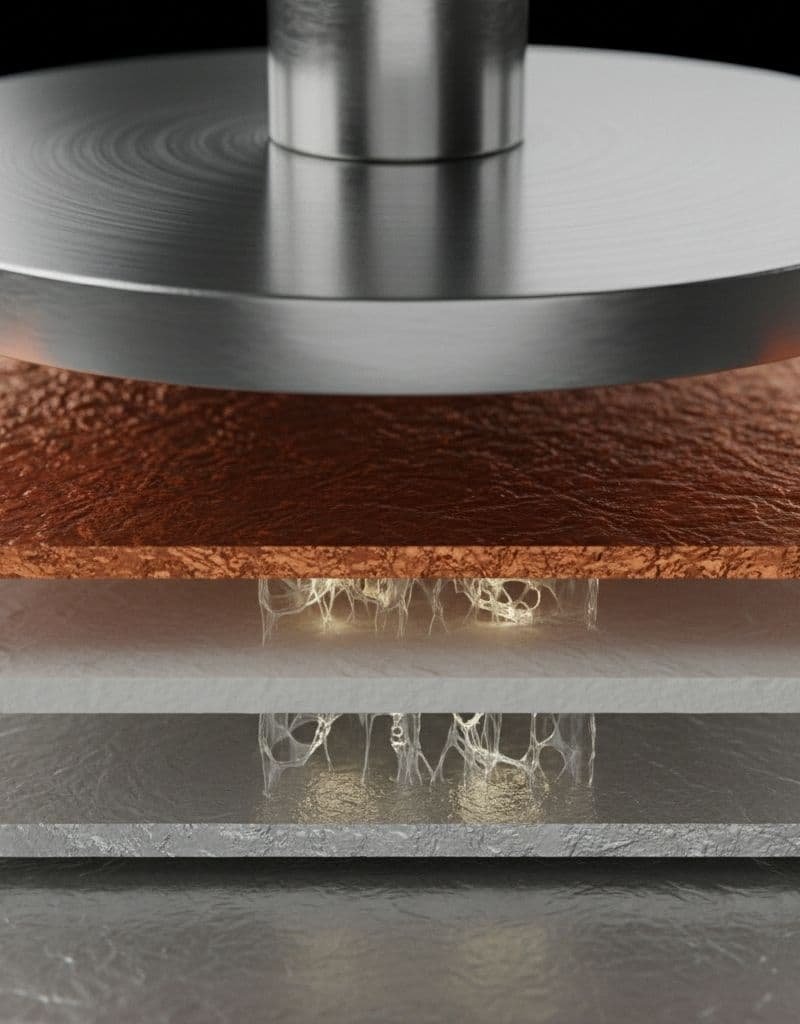

2. Compression is Key: To make a high-performance battery, the layered structure must be tightly packed. Engineers carefully seal the battery using either a vacuum or pressure technique and then apply immense force using a hydraulic pressure mold.

3. Why Compression? Tight compression is necessary because it minimizes the air gaps and voids at the solid-solid interfaces. As I know from building battery prototypes, poor contact here increases interfacial resistance, which kills performance. Careful sealing ensures all the solid-state battery components are tightly packed together. This guarantees the best possible battery performance and longevity.

Step 5: Test the Battery

Testing verifies that the solid-state battery operates correctly for its designed purpose. The battery evaluation process involves several charge and discharge cycles, and during those cycles, the testing records the voltage and the capacity.

- Capacity Testing: Use a battery tester to measure the amount of energy the battery can store and release.

- Voltage Testing: Check the voltage levels to ensure they’re within the expected range for the battery type.

- Safety Testing: It’s important to test for potential safety issues, like overheating or short-circuiting. Solid-state batteries are safer than liquid-based batteries but must be properly tested.

Testing your battery before practical use helps eliminate potential problems within the battery.

Detailed Guide: Testing Methods for Solid-State Battery Longevity

Conclusion

Creating a solid-state battery is a balance of science and craftsmanship. Prioritize material compatibility, optimize electrolyte thickness, and test thoroughly to avoid flaws. While not mainstream, these batteries offer unmatched potential for fast charging and longevity. Dive into the process, embrace trial and error, and contribute to a safer energy revolution.

FAQs For “How to Make a Solid State Battery?”

What are the raw materials for solid-state batteries?

You need lithium metal (anode), cathode compounds (e.g., lithium cobalt oxide), solid electrolytes (ceramic/sulfide), binders, and metal foils (copper/aluminium).

Why compress battery layers during assembly?

Tight compression reduces the resistance between electrodes and electrolytes. Use a hydraulic press to ensure optimal ion transfer.

What is the role of the anode and cathode in a solid-state battery?

The anode stores lithium ions, while the cathode releases them during discharge. Together, they work with the solid electrolyte to transfer energy safely and efficiently.

How do you assemble a solid-state battery?

Technicians assemble the battery by layering the anode, the solid electrolyte, and the cathode. Workers then seal the assembled layers tightly with vacuum or pressure methods. This process guarantees proper contact among the layers and stops air from negatively influencing battery performance.

How do you test a solid-state battery after making it?

Testing involves capacity tests (energy storage measurement), voltage tests (stability check), and safety tests to detect overheating or short circuits before practical use.

Can you make a solid-state battery at home?

Yes, you can attempt a DIY solid-state battery or a simple solid-state battery prototype, but it requires specialized materials, proper glove box handling of lithium metal, and a controlled, low-humidity environment to ensure safety and function. Large-scale, functional production is extremely complex.

What are the challenges of making solid-state batteries?

Challenges include high manufacturing costs, material stability issues, and production scalability. Researchers are working on improving these aspects for commercial adoption.