Electric vehicle batteries don’t just stop working when they’re old—they can be recycled! Recycling EV batteries helps recover valuable materials like lithium, cobalt, and nickel, which can be used to make new batteries. The process minimizes waste, conserves resources, and helps protect the environment. By recycling, we’re supporting clean energy and creating a sustainable future.

How Are EV Batteries Recycled?

1. Collection and Transportation

EV batteries marked as unusable are collected from cars and repair shops and transported to recycling centers.

2. Initial Testing and Sorting

Upon receiving the batteries at the recycling center, they are checked for capacity and health. Batteries that can still perform important functions can be repurposed for energy storage systems instead of being recycled immediately.

Read more: How to Check EV Battery Health?

3. Disassembly

Batteries that no longer serve a purpose are disassembled. The battery management system and other electronic components are extracted to separate the battery cells from the materials that offer value.

4. Safe Discharge

The energy that remains stored within the battery cells is let out in a controlled manner to prevent any injuries during the recycling procedure.

5. Mechanical Processing

Battery cells are shredded and crushed to make smaller pieces that can be separated. The distinct materials are refined and worked on while the atmosphere is monitored to avoid exposure to harmful elements.

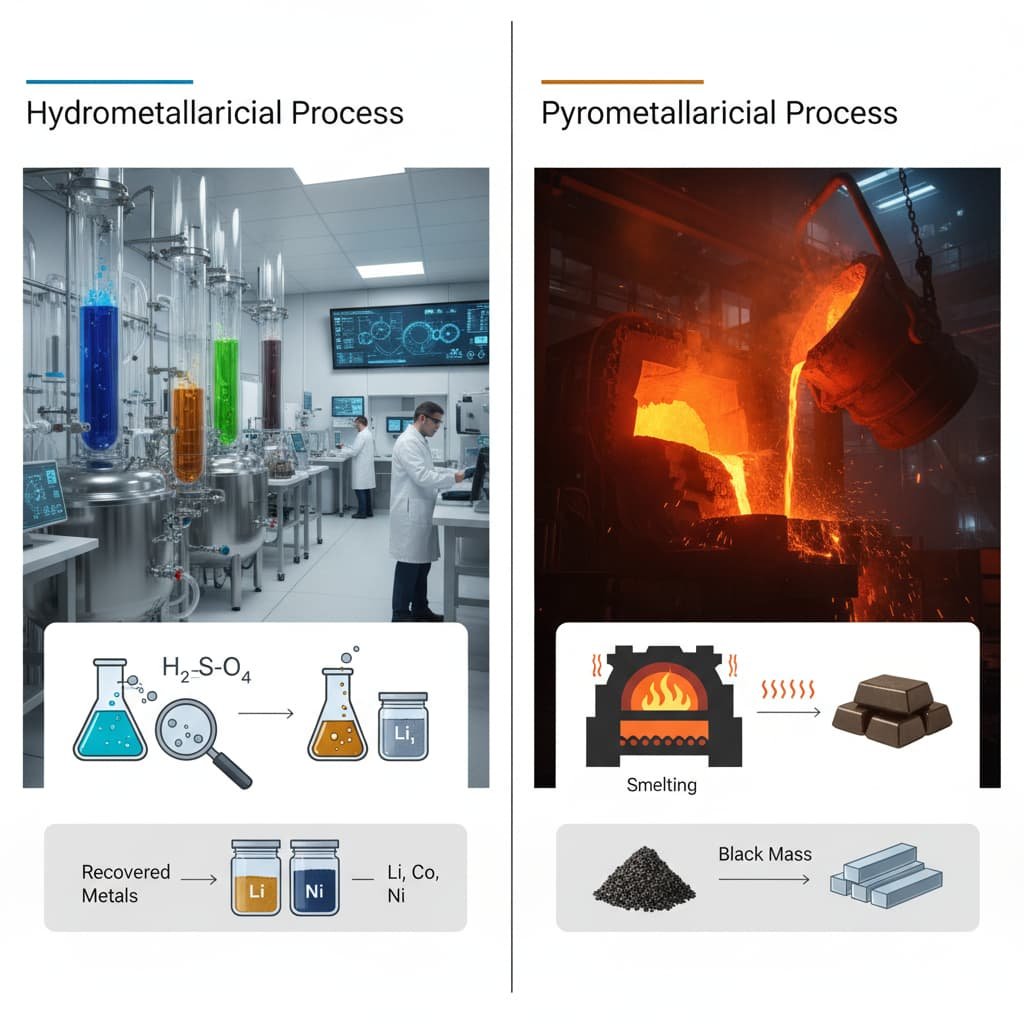

6. Hydrometallurgical Process

Leaching uses chemicals to extract valuable metals. These metals include lithium, cobalt, nickel, and manganese. The process dissolves these metals. Technicians then separate the dissolved metals using other chemical processes.

7. Pyrometallurgical Process

This process involves heating materials in a furnace at high temperatures. The stove burns off the lower-value materials, allowing metals to be recovered through smelting.

8. Refinement and Purification

The materials are further purified to the desired quality, which allows them to be reused in new battery production or for other uses.

9. Recycling of By-products

Other battery components, such as plastics and electrolytes, are recycled or properly disposed of by local laws and regulations.

10. Preparation for Reuse

The reclaimed metals are then processed for reuse into new types of batteries or other goods, such as robotics, thereby completing the materials cycle.

What Batteries Cannot Be Recycled?

- Alkaline Batteries (AAA, AA, C, D, 9V)

- Zinc-Carbon Batteries

- Zinc-Air Batteries (Hearing Aids)

- Mercury Batteries

- Silver-Oxide Batteries (Watches, Medical Devices)

- Disposable Lithium Batteries

Is lithium Battery Recycling Profitable?

Lithium battery recycling can be profitable, but profitability depends on several key factors, including technology, market demand, and operational scale. Several reasons explain potential profitability.

1. Valuable Materials

These materials include lithium, cobalt, nickel, and manganese. They are in high demand, and manufacturers use them in new batteries and other products.

2. Cost of Raw Materials

Rising raw material costs make recycling more attractive. Recycled materials become a cost-effective option for manufacturers.

3. Technological Advances

New technologies make material extraction cheaper and more efficient. These advancements boost profitability.

4. Regulatory Support

Many governments encourage or mandate battery recycling. Regulations can provide financial incentives, and subsidies can support recycling operations.

3. Environmental Considerations

They invest in recycling to minimize environmental impact. Recycling enhances corporate responsibility.

Largest Lithium Battery Recycling Companies In USA

| Company | Headquarters | Capacity (Annual) | Key Services | Major Partners |

|---|---|---|---|---|

| Redwood Materials | Carson City, NV | 100,000+ tons | EV battery recycling, material recovery | Tesla, Ford, Toyota, Panasonic |

| Li-Cycle | Toronto (U.S. hubs) | 30,000+ tons | Hub-and-spoke recycling, lithium recovery | LG, GM (Ultium Cells), Apple |

| Cirba Solutions | Charlotte, NC | 100,000+ tons | Li-ion, NiMH, lead-acid recycling | Honda, Panasonic, Duracell |

| Ascend Elements | Westborough, MA | 30,000+ tons | Closed-loop recycling, Hydro-to-Cathode™ | Honda, Subaru |

| ABTC | Reno, NV | 20,000+ tons | Lithium extraction, mine tailings | Ford, BASF |

| Retriev Technologies | Lancaster, OH | 50,000+ tons | Battery recycling since 1996 | Auto OEMs, tech firms |

| TES | Singapore (U.S. hubs) | 50,000+ tons | Global e-waste & battery recycling | Samsung, Mercedes-Benz |

Swipe or scroll horizontally to see the full table content

What Are The Disadvantages Of Recycling Lithium Batteries?

The recycling process for lithium batteries is expensive due to its particular technology and energy consumption. As a result, the process becomes less profitable if the price of raw materials is low.

1. Complex Technology

Battery repairs are costly and difficult because different battery types require specialized, complex technology. Damaged batteries also add to the complexity and cost.

2. Safety Risks

Improperly handled lithium batteries pose fire and explosion risks. Strict safety procedures are essential.

3. Environmental Impact

Pollution is often attributed to processing lithium batteries into their eco-friendly components; recycling calls for harsh chemicals that, if not properly supervised, can create risks.

4. Low Recovery Efficiency

Existing recycling processes cannot capture all valuable materials. Many materials are misplaced or devalued over time, making recycling less worthwhile.

5. Regulatory and Logistical Challenges

Transporting and adhering to battery regulations decreases productivity. Sorting, collecting, and transporting used batteries creates more logistical problems.

6. Limited Infrastructure

A recycling problem is caused by a lack of facilities in certain areas with abundant used batteries.

7. Innovation and Adaptation Delays

Battery technology is rapidly changing. However, recycling methods are not making the necessary changes fast enough, which makes recycling new batteries less efficient.

FAQs

Does China Recycle Batteries?

Yes, China recycles batteries extensively. The country has strict regulations and state-backed programs to recycle lithium-ion batteries, especially from EVs. Major companies like CATL and GEM operate large-scale recycling facilities. China aims to recover 90%+ of materials like lithium, cobalt, and nickel to reduce reliance on mining.

What Does Tesla Do With Old Batteries?

Tesla recycles or repurposes old batteries. They partner with firms like Redwood Materials (founded by a Tesla co-founder) to recover up to 95% of key materials. Some batteries are refurbished for energy storage (e.g., Powerwall) before recycling. Tesla also recycles at its own Gigafactories.

Are Tesla Batteries Recycled?

Yes, Tesla batteries are recycled. The company claims 100% of scrapped batteries are recycled, with recovered materials reused in new batteries. Tesla’s closed-loop system aims to cut costs and environmental impact. However, full-scale recycling is still ramping up globally.

Can EV batteries Be Recycled?

Yes, EV batteries can be recycled. The process applies to recovering valuable materials like lithium, cobalt, nickel, and manganese, which can be reused in new batteries or other applications.

What Is The Recycling Rate For EV Batteries?

Approximately 90-95% of an EV battery can be recycled. EV batteries contain valuable materials, including metals like lithium, cobalt, nickel, aluminum, plastics, and electrolytes.

Is lithium recyclable?

Yes, Lithium is recyclable. However, lithium recycling is complex and differs from paper or plastic recycling. Lithium-ion batteries power many devices, including electric cars and smartphones. The batteries contain reusable lithium, which can be extracted and reused. Current lithium recycling methods are not simple or efficient.

Conclusion

EV battery recycling is not just possible—it’s essential. With 90–95% of materials recoverable, recycling slashes mining demand, cuts environmental harm, and fuels a sustainable energy future. Companies like Tesla and Redwood Materials are leading the charge, repurposing old batteries and transforming them into new ones or energy storage systems. At the same time, China’s aggressive recycling programs set global benchmarks.

Yet challenges remain: high costs, safety risks, and evolving tech demand more intelligent policies and innovation. Despite hurdles, advancements in hydrometallurgy, AI-driven sorting, and global regulations (like the U.S. Bipartisan Infrastructure Law) are accelerating progress.