Have you noticed your electric car feels slow on a cold winter morning? Or does its range drop quickly during a summer heatwave? This happens because of your car’s battery temperature.

Most electric cars are powered by lithium-ion batteries, which can be sensitive in certain conditions. These batteries perform optimally in an environment that is neither hot nor cold—it’s like their comfort zone.

The Battery Thermal Management System, or BTMS, helps with this. You might not see it advertised, but this system works hard behind the scenes. It’s like a special climate control just for your car’s battery.

Why is this important? Maintaining the battery at the proper temperature is crucial for three main reasons:

1. Performance: Getting the power and range you expect.

2. Safety: Preventing dangerous overheating situations.

3. Lifespan: Making sure your expensive battery lasts as long as possible.

In this guide, we’ll dive into the world of EV battery thermal management systems. We’ll explore why temperature is such a big deal for lithium-ion batteries, look at the different hows – the various types of BTMS used in EVs today, from simple air cooling to advanced liquid systems – and discuss what the latest advances in battery cooling and heating mean for the future of electric driving and for you as a driver.

The Battery “Goldilocks Zone”: Not Too Hot, Not Too Cold

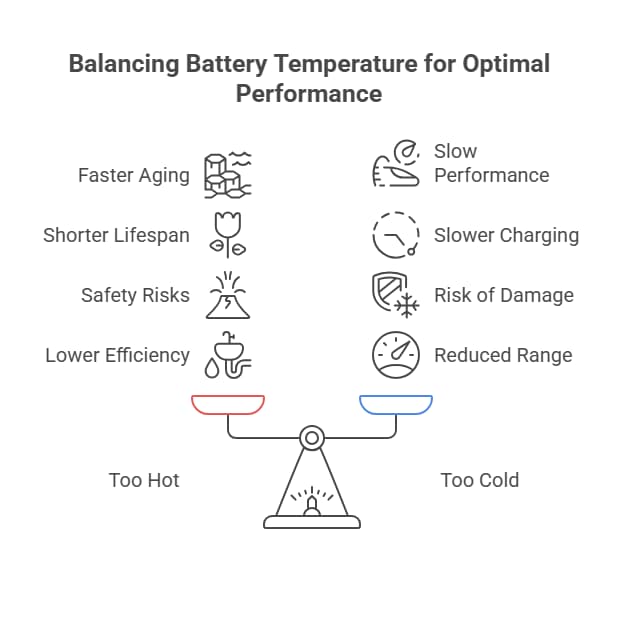

Just like Goldilocks looked for the perfect porridge, your electric vehicle (EV) battery has an ideal temperature range. In this range, it works best.

Experts say this ideal temperature is between 15°C and 35°C (60°F to 95°F). Some sources, like Thermtest, even suggest peak performance is often between 20°C and 30°C (68°F to 86°F). A research paper from MDPI states that keeping these batteries between 12°C and 37°C is essential for top performance.

Why this specific range? It’s all about the battery’s internal chemistry. Within this “Goldilocks zone,” the chemical reactions that store and release energy happen most effectively and safely.

But what happens if the temperature goes outside this ideal range? Let’s find out:

When it’s Too Hot:

- Faster Aging: Heat speeds up chemical reactions that degrade the battery. Think of food spoiling faster in the sun. Your battery loses capacity and power over time.

- Shorter Lifespan: This faster aging directly shortens the battery’s overall life.

- Safety Risks: Too much heat can cause a dangerous chain reaction called thermal runaway. Thermtest warns that extreme conditions increase the risk of thermal runaway. This can lead to fires or explosions. Good cooling is crucial to prevent this.

- Lower Efficiency: More energy can turn into wasted heat. This reduces overall efficiency.

When it’s Too Cold:

- Slow Performance: Chemical reactions significantly slow down in cold temperatures, which prevents the battery from providing power quickly. This leads to slower acceleration and a sluggish feeling. Thermtest calls this “slowing down the power flow.”

- Slower Charging: The battery cannot accept a charge as quickly. Charging times become much longer in freezing temperatures.

- Reduced Range (Temporary): When cold, the battery cannot access all its stored energy, temporarily reducing driving range.

- Risk of Damage: Charging a very cold lithium-ion battery (especially below freezing) can damage it. Lithium metal can build up on the anode surface, causing permanent damage. This reduces capacity and can even create safety risks later.

Therefore, a primary goal of any Battery Thermal Management System (BTMS) is not just to cool things down, but to actively manage the temperature, heating when necessary, cooling when required, To ensure the entire battery pack remains in its optimal operating range. Another critical job is ensuring temperature uniformity, meaning keeping all the individual cells within the pack at roughly the same temperature. Large temperature differences between cells can cause them to age differently, unbalancing the pack and reducing its overall life and performance.

Where Does Battery Heat Come From?

Batteries don’t work well when they get too hot. But where does this heat come from, even when it’s not hot outside?

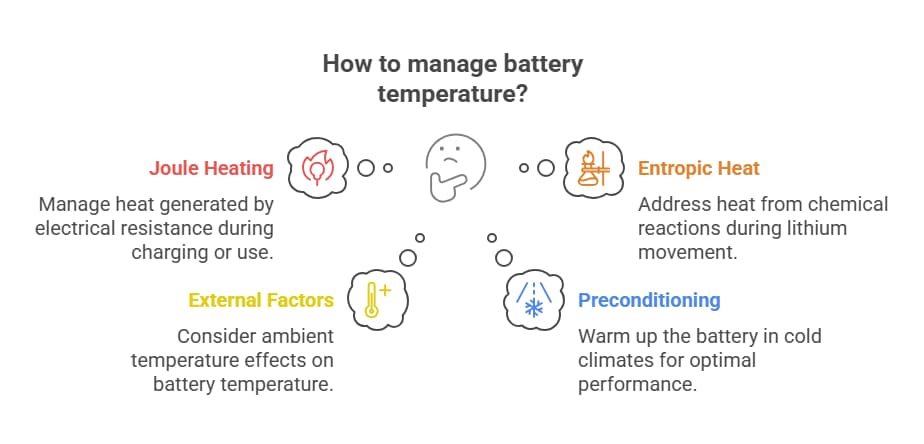

There are two main ways a battery creates its own heat:

Joule Heating (Resistance Heating)

This is the biggest reason for heat. When electricity flows through the battery (while charging or using it), parts inside the battery resist this flow. The key components are electrodes, electrolyte, and connectors. Resistance converts some electricity into heat. Think of an old light bulb getting hot. The more electricity that flows (like during fast acceleration or fast charging an electric vehicle), the more heat the battery generates.

Entropic Heat (Heat From Chemical Reactions)

This heat comes from the chemical changes as lithium moves in and out of the battery materials. Depending on the battery’s makeup and how much charge it has, these reactions can create a little more heat or even cool the battery slightly. However, Joule heating usually produces much more heat.

Of course, external factors like high ambient temperatures also add to the thermal load the BTMS needs to manage.

But thermal management isn’t just about cooling. In cold climates, the battery often needs help warming up. This is where battery preconditioning or pre-heating comes in. Before you start driving on a cold morning, or especially before attempting to fast-charge, the BTMS might heat the battery pack to bring it closer to its optimal operating temperature. This ensures you get better performance, avoid potential damage from charging while frozen, and can access faster charging speeds.

Types of Battery Thermal Management Systems

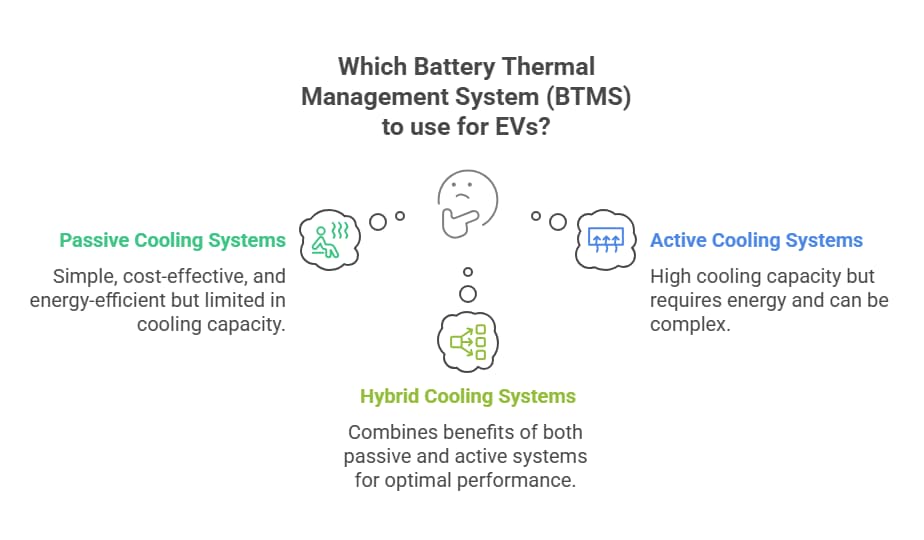

So, how do EVs actually manage this crucial temperature balancing act? Engineers utilize different types of Battery Thermal Management Systems (BTMS). We can broadly group these into three main categories:

Passive Cooling Systems: These systems don’t use any extra power to operate. They rely on natural processes and clever material choices to dissipate heat.

Active Cooling Systems: These are the workhorses. They use components like pumps, fans, or compressors – requiring energy – to actively move heat away from the battery or bring heat to it.

Hybrid Cooling Systems: As the name suggests, these combine elements of both passive and active systems, aiming to get the best performance and efficiency.

Let’s examine each type in more detail.

1. Passive Cooling Strategies: Simple But Limited

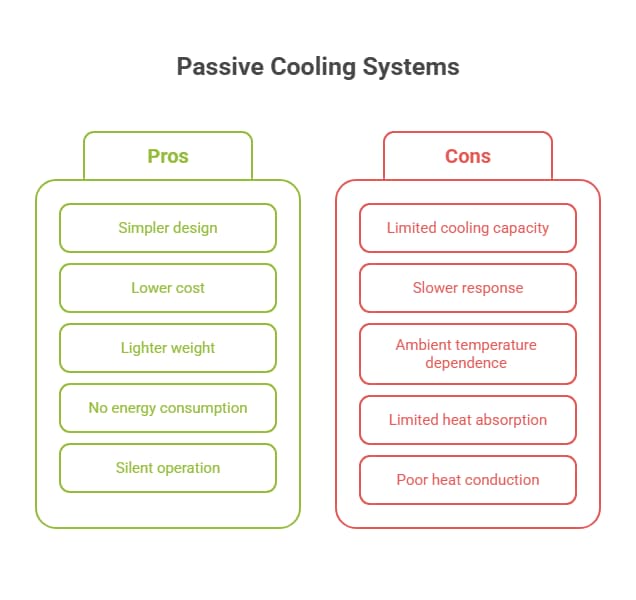

Passive cooling systems are simple and attractive because they are lighter, cheaper, and do not use extra energy from the battery. However, their cooling power is often limited.

Here are common passive cooling methods:

a. Natural Convection/Radiation

This is the most basic method. It lets heat escape from the battery casing into the air. This method only works for very low-power devices.

b. Heat Sinks & Fins

These metal parts, usually aluminum, are attached to the battery modules or casing. They increase the surface area exposed to the air, which helps transfer heat away from the battery.

c. Heat Pipes / Vapor Chambers

These sealed devices contain a small amount of fluid, like water. When the battery heats up, the fluid at one end turns into vapor. The vapor quickly moves to the cooler end and turns back into liquid, releasing heat. The liquid flows back through the wick. These devices are very good at moving heat quickly over short distances with little temperature change.

d. Phase Change Materials (PCM)

These materials, often paraffin waxes or salt hydrates, melt and solidify within the battery’s ideal temperature range.

- How they work: As the battery gets hot and reaches the PCM’s melting point, the PCM absorbs a lot of heat as it melts, keeping the battery’s temperature stable. When the battery cools, the PCM hardens and releases the stored heat.

- Pros: They are excellent for absorbing sudden heat, like during fast charging, and for making the temperature even across the battery pack.

- Cons: They can only absorb a limited amount of heat before they fully melt. Their effectiveness can be low because heat does not spread quickly through them. However, researchers are improving this by adding conductive materials like graphite or graphene to create Nano-Enhanced PCMs (NEPCMs).

Overall Pros & Cons of Passive Systems:

| Pros | Cons |

|---|---|

| Simpler design | Limited cooling capacity (struggle with high heat loads) |

| Lower cost | Slower response to temperature changes |

| Lighter weight | Highly dependent on ambient temperature |

| No energy consumption (parasitic load) | Limited cooling capacity (struggles with high heat loads) |

| Silent operation |

e. Passive Cooling: How PCMs Work

Let’s look at Phase Change Materials (PCMs) again. They offer a smart, hands-off way to manage heat. Think of a material like wax. It melts exactly when your battery gets a bit too warm, for example, at 30°C.

- Heat Absorption: As the battery makes heat, the PCM soaks it up. The PCM’s temperature does not go up much. All that energy helps melt the wax. This is called a phase change.

- Temperature Control: This process slows down how fast the battery’s temperature rises. This is useful during tasks that create a lot of heat, like fast charging or quick acceleration.

- Heat Release: Later, the battery cools down. For example, this happens when the car is parked. Then, the PCM turns solid again. It slowly releases the heat it stored.

The main problem is that once all the PCM melts, it cannot soak up more heat. It needs to cool down and turn solid first. Also, many PCMs do not conduct heat well. Using a small flame to melt a large block of wax will only melt the area directly around the flame. To fix this, researchers are mixing PCMs with materials that conduct heat very well:

- Graphite/Graphene: Adding flakes or networks of graphite or graphene helps heat move quickly through the PCM. This helps the phase change material (PCM) melt and absorb heat more efficiently. Recent studies call these Nano-Enhanced PCMs (NEPCMs).

- Metal Foams: Putting the PCM inside a spongy metal structure also improves heat movement.

While not usually sufficient as the sole BTMS for a high-performance EV, PCMs are valuable components in hybrid cooling systems, helping to manage peak temperatures and improve overall temperature uniformity across the battery pack.

2. Active Cooling Strategies

High-performance electric vehicles (EVs) need active cooling. This is especially true for EVs with big battery packs and fast charging. Active cooling systems use energy. They provide strong and controlled cooling and heating for EV batteries.

Here are the main types:

Air Cooling

- How it works: Fans circulate air over the battery components, drawing from either the outside environment or the car’s air conditioning system.

- Good points: It is simpler and usually cheaper than liquid cooling.

- Bad points: Its cooling power depends on air temperature and how fast the air flows. It may not work well in very hot weather. It can be hard to cool all parts of large batteries evenly. Fans use energy and can be noisy.

- Improvements: Designs now focus on better airflow. They also use honeycomb shapes to move heat better.

Liquid Cooling: (Most common in today’s EVs)

- How it works: A liquid coolant, like antifreeze, is pumped through pipes and channels. These channels are often in metal plates called “cold plates.” These plates touch the battery parts and take heat away. The warm coolant moves to the radiator at the front of the car, where it is cooled by outside air before returning to the battery.

Types

- Good points: It removes heat very well, even in hot weather. It keeps the battery temperature very even. It helps prepare the battery for use by circulating warm coolant. An electric heater or waste heat often warms this coolant.

- Bad points: The system is more complex, involving a pump, radiator, hoses, and coolant. It is also more costly and heavier compared to air cooling systems. Leaks can happen. The pump and radiator fan use energy.

Refrigerant Cooling (Uses AC System)

- How it works: This system uses the car’s air conditioning liquid directly. The liquid expands and evaporates inside a chiller or heat exchanger connected to the battery, providing very strong cooling.

- Good points: It cools very well. It is good for extreme heat or very powerful batteries. It cools quickly.

- Bad points: It makes the AC system much more complex and can use a lot of energy, which might reduce the car’s range.

Thermoelectric Cooling (TEC / Peltier)

- How it works: These devices are solid. When electricity passes through, one side heats up while the other cools down. Place the cold side against the battery. Heat from the hot side goes away, providing cooling. Reversing the electric current can also provide heating.

- Good points: They are solid, so they have no moving parts, which means they can be very reliable. They can also heat and cool, allowing for very precise temperature control.

- Bad points: They are generally less energy efficient than other cooling methods. This means they use more energy for the cooling they provide. They are often most effective for small, specific heating or cooling tasks. Additionally, they can be integrated into a hybrid cooling system.

Exploring Active Cooling: Immersion Cooling Explained

Immersion cooling is a liquid cooling method. It is getting a lot of attention for very high-performance uses.

- What it is: The battery cells are completely covered in a special liquid. This liquid does not conduct electricity. The coolant isn’t circulating around the battery cells.

- Why it works well:

- Direct Contact: The cooling liquid touches almost all surfaces of every cell. This transfers heat very well and evenly.

- Even Temperature: This direct contact reduces temperature differences between cells. It also reduces differences across a single cell’s surface. This is good for battery life and safety.

- Safety: Some of these liquids can also stop fires. This adds more safety against battery overheating.

- Challenges:

- Fluid Choice: Choosing the right liquid is very important. It must not conduct electricity. It needs to transfer heat well. It must not harm battery materials over time. It should not be toxic. Ideally, it should be affordable.

- Sealing: The battery pack must be perfectly sealed. This keeps the liquid inside.

- Weight: The liquid in the battery pack adds to its overall weight.

- Maintenance: Working on a battery pack that uses immersion cooling might be more complicated.

Immersion cooling is still an advanced method. However, companies are developing and using it for demanding uses like electric hypercars. It may also be used in future mainstream EVs that need high-speed charging.

3. Hybrid Cooling Systems: The Best of Both Worlds?

No single cooling method works perfectly everywhere. So, engineers are now using hybrid cooling systems more often. These systems combine the best parts of different cooling technologies.

- What they are: They mix active and passive cooling methods, or even different active methods.

- Why use them: To make cooling systems work better, use less energy, and cost less in various situations.

Examples:

- Phase Change Material (PCM) and Liquid Cooling: PCM handles quick bursts of heat, like during fast charging. The liquid system then deals with the regular, ongoing heat and can also provide warmth.

- Air and PCM: Air does the basic cooling. PCM helps manage very hot temperatures and keeps the temperature even.

- Liquid and Thermoelectric Cooler (TEC): Liquid cooling provides the main cooling or heating. TECs offer very exact temperature control for specific parts or for quick, focused cooling or heating.

Growing Trend: Hybrid systems are a major new development. Researchers say a hybrid cooling system uses at least two types of battery thermal management systems (BTMS) to improve how well they manage heat.

While hybrid systems offer custom solutions, they can be more complex and harder to control.

Comparison Of EV Battery Thermal Management Systems (BTMS)

| Feature | Air Cooling | Liquid Cooling (Indirect/Cold Plate) | PCM (Passive/Hybrid) | Hybrid (e.g., Liquid + PCM) |

|---|---|---|---|---|

| Cooling Power | Low to Moderate | High | Moderate (Peak Load Absorption) | High to Very High |

| Heating Ability | Limited (Cabin Air) / None (Ambient) | Good (with heater) | None (Passive) | Good (if liquid component included) |

| Temp. Uniformity | Fair to Poor | Good to Excellent | Good (during phase change) | Good to Excellent |

| Complexity | Low | Moderate to High | Low (Passive) / Moderate (Hybrid) | High |

| Cost | Low | Moderate to High | Low to Moderate | High |

| Weight/Size | Low | Moderate | Moderate to High (PCM density) | Moderate to High |

| Energy Use | Low (Fans) | Moderate (Pump, Fans) | None (Passive) / Low (Hybrid) | Moderate to High |

| Pros | Simple, low cost, lightweight | Very effective cooling/heating, uniform temps | Simple, low-cost, lightweight | Optimized performance, handles diverse loads |

| Cons | Limited power, poor uniformity, noisy fans | Complex, costly, potential leaks, pump power | Limited total capacity, slow heat release | Very complex, high cost, potential issues |

| Typical Use | Older EVs, Mild Climates, Low Power | Most Modern EVs, High Performance | Niche applications, Hybrid Systems | Passive heat absorption improves uniformity |

Source: Compiled from information presented in this article and general EV technology knowledge.

The Brains Behind The Operation: BMS And Thermal Control

A sophisticated Battery Thermal Management System (BTMS) doesn’t operate in isolation. It’s controlled by the overarching Battery Management System (BMS) – the central computer for the battery pack.

The BMS plays a critical role:

- Monitoring: It constantly receives data from numerous temperature sensors placed throughout the battery pack, along with voltage, current, and State of Charge (SOC) information.

- Analyzing: It processes this data using complex algorithms to understand the battery’s current thermal state and predict future needs.

- Controlling: Based on its analysis, the BMS sends commands to the BTMS components. It decides when to turn on the coolant pump, adjust fan speeds, open or close valves, activate heaters, or engage the AC system for battery cooling.

Effective lithium-ion battery temperature control relies heavily on the intelligence programmed into the BMS. It needs to make smart decisions to balance cooling/heating needs with energy consumption and component wear.

AI And Future Trends In BTMS

The field of EV battery thermal management is rapidly evolving. Here are some exciting trends that are shaping its future:

1. AI and Machine Learning Take Over

AI is a major new development. Instead of only following fixed rules, AI helps battery thermal management systems (BTMS) become smarter and more adaptable.

2. Predictive Thermal Management

A big challenge is creating systems that can guess temperature changes before they happen. AI models, like those that learn patterns over time, can predict future battery temperatures. They use information like how you drive, your planned route (including hills), the weather, and the battery’s current health.

3. Better Control Strategies

With these predictions, AI can make BTMS work in the best way. For example, it might cool the battery before a fast charge. It could also use less cooling energy during gentle driving. A method called “reinforcement learning” helps the system learn the best cooling or heating plans through practice.

4. Early Problem Detection

Artificial intelligence has the ability to analyze small details within sensor data. This helps it find problems like internal short circuits or cooling system issues much earlier than old methods. This makes batteries safer.

New Materials Scientists are working on better materials:

- Coolants that work better and are good for the environment.

- Phase-change materials (PCMs) that can store more energy and transfer heat better.

- Improved materials that help heat move efficiently between battery cells and cooling parts.

5. Immersion Cooling

This method involves placing battery cells directly into a special liquid that doesn’t conduct electricity. It’s becoming popular for high-performance electric vehicles. This is because these vehicles need to get rid of a lot of heat. Immersion cooling can make temperatures very even and transfer heat very well.

6. Integrated Designs

Future designs are moving towards “Cell-to-Pack” or “Cell-to-Chassis.” This means battery cells are built directly into the vehicle’s body. This allows thermal management parts to fit more efficiently, saving space, weight, and possibly money.

Cell-To-Pack and Cell-To-Chassis Integration

A major trend in battery design is changing how battery packs are built. This aims to improve how they manage heat.

- Old Way: Batteries were often grouped into smaller parts called modules. These modules then went into a bigger pack. Cooling parts were added around the modules.

- Cell-to-Pack (CTP): This method removes the module cases. It puts cells directly into the battery pack. This saves space and makes the pack lighter.

- Cell-to-Chassis (CTC): This takes integration a step further. It puts cells directly into the car’s frame.

How This Helps with Heat Management:

- More Space: Removing module parts creates more room. This enables improved positioning of cooling channels or plates. It can also lead to larger cooling surfaces closer to the battery cells.

- Better Heat Flow: Integrating cooling directly shortens the distance heat travels. Heat moves from the cell to the coolant more efficiently.

- Frame as Cooler: With CTC, parts of the car’s frame can act as heat sinks and have built-in cooling channels.

These integrated designs aim for several benefits. They allow more battery power in the same space, make the battery lighter and cheaper, and can manage heat more effectively. However, these designs may complicate repairs.

Conclusion

Thermal management systems for electric vehicle (EV) batteries are very important. They are not just simple cooling systems. These complex systems directly affect how an EV works. They impact how far it can travel, how fast it can charge, and how long its expensive battery will last. The most important aspect is that they guarantee the safety of the battery.

Simple cooling systems exist, but modern EVs need stronger, smarter systems. These often combine different technologies, which are always improving. Examples include advanced liquid cooling systems and new materials that undergo phase changes. Artificial intelligence (AI) is also showing promise for predicting and controlling temperature.

The main goal is to keep the battery at the ideal temperature. Engineers work hard to achieve this balance. For drivers, this means many benefits: batteries last longer, performance stays steady, charging is faster, and there’s less to worry about.

So, when you charge your EV or enjoy its smooth ride, remember that the system works hard to keep the battery at its best. Future battery temperature control systems will be even smarter and more efficient, leading to even better electric vehicles.

FAQs

What is the ideal temperature for an EV battery?

Most experts agree that the ideal range is between 15°C and 35°C (about 60°F to 95°F). Performance and longevity are best within this “Goldilocks zone.” Both extreme heat and cold can negatively impact the battery.

Why does my EV charge more slowly in the winter?

Cold temperatures slow down the chemical reactions inside the lithium-ion battery. This reduces the rate at which the battery can safely accept the charge. Many EVs use their thermal management system to preheat the battery before or during charging in cold weather to improve speeds, but it still might be slower than in warmer conditions.

What is thermal runaway in an EV battery?

Thermal runaway is a dangerous chain reaction where excessive heat causes further chemical reactions, generating even more heat. This can damage the battery and may cause smoke, fire, or explosion. Effective battery thermal management systems are crucial for preventing this by keeping temperatures under control.

Does fast charging damage my EV battery due to heat?

Fast charging generates more heat than slower charging. While EV thermal management systems are designed to handle this heat and protect the battery, frequent reliance solely on high-power DC fast charging can contribute to slightly faster battery degradation over the long term compared to slower AC charging. Modern BTMS minimizes this risk significantly.

What are the main types of EV battery cooling?

The main types are passive cooling (using heat sinks, PCMs), active air cooling (using fans), and active liquid cooling (circulating a coolant). Liquid cooling is most common in modern EVs due to its effectiveness. Hybrid systems combine multiple methods.

What is battery preconditioning?

Battery preconditioning is when the EV’s thermal management system actively heats the battery pack, usually in cold weather. This is done before driving to improve performance or before fast charging to allow for faster charging speeds and prevent potential damage from charging a frozen battery.

How does AI help with battery thermal management?

AI can analyze data (such as driving patterns, weather, and routes) to predict future battery temperatures and proactively optimize cooling or heating. This can improve efficiency, enhance battery life, and provide earlier warnings of potential thermal issues compared to traditional reactive systems.