The cost of electric vehicle (EV) batteries is one of the biggest factors influencing the price of EVs, and one of the most misunderstood. As we move further into 2025, understanding how EV battery costs per kilowatt-hour (kWh) affect vehicle prices and the future of driving is essential.

Let’s break down what you need to know about EV battery costs per kWh, why they matter, and how they’re shaping the future of transportation.

Current Electric Car Battery Cost Per kWh

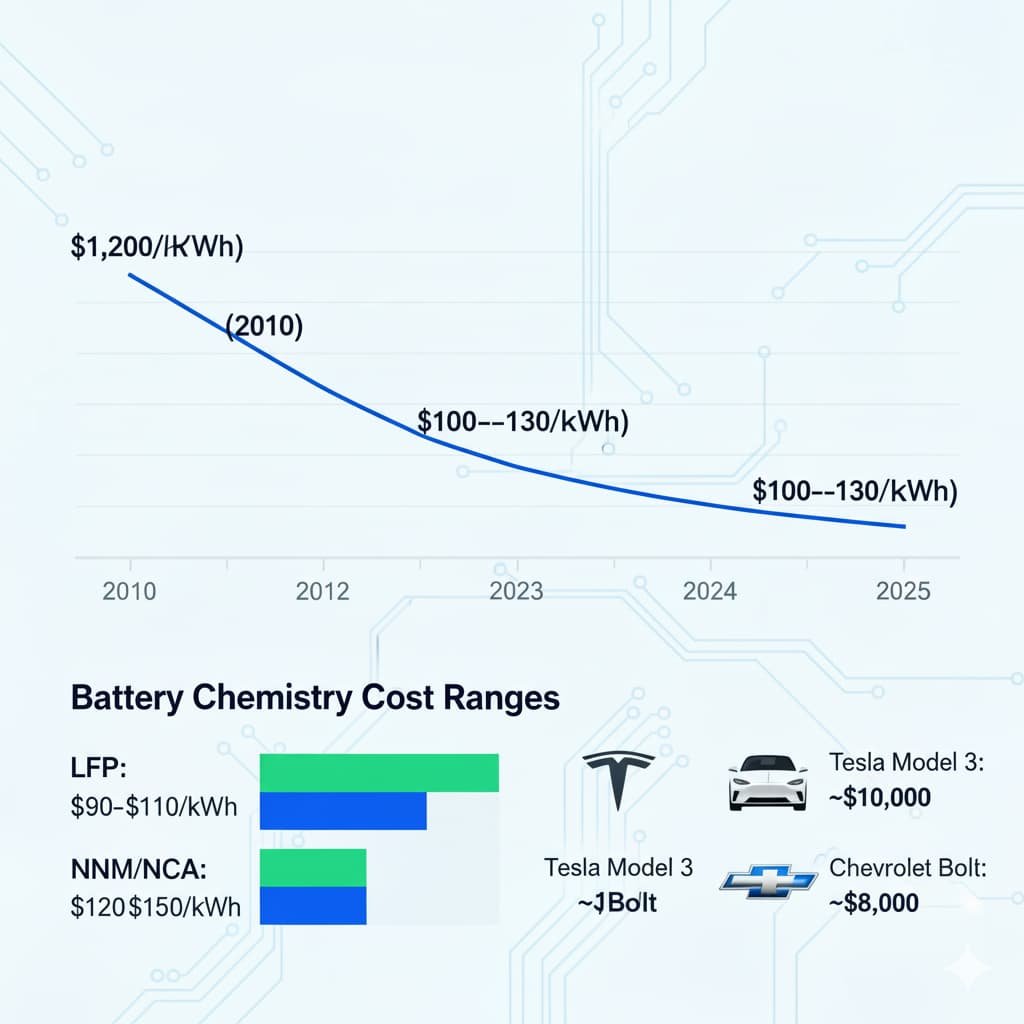

An electric vehicle’s (EV) battery pack typically costs between $100 and $130 per kilowatt-hour (kWh) in 2025, reflecting a continued decline from about $1,200 per kWh in 2010. This remarkable decrease has made EVs more accessible.

For perspective, the battery packs in cars like the Tesla Model 3 cost roughly $7,000 to $10,000, not the entire vehicle price. Similarly, the Chevrolet Bolt battery pack costs approximately $7,000 to $9,000, rather than the $84,500 to $97,500 total vehicle cost.

Battery cost varies by chemistry and brand:

- Lithium Iron Phosphate (LFP) batteries are among the cheapest, at $90 to $110 per kWh. These durable batteries are common in Tesla’s Standard Range models and many BYD vehicles.

- Nickel-based batteries such as Nickel Manganese Cobalt (NMC) and Nickel Cobalt Aluminum (NCA), have higher energy density and cost around $120 to $150 per kWh. These are found in luxury EVs, including Porsche and Lucid models.

What Is KWh?

A kilowatt-hour (kWh) is a unit of energy that measures the amount of electricity used over time. It represents the amount of energy consumed when a device with a power rating of one kilowatt (kW) operates for one hour.

- Kilowatt (kW): A unit of power equal to 1,000 watts.

- Hour (h): A unit of time.

Energy Consumption: kWh measures the total energy used, calculated as:

Energy (kWh)=Power (kW)×Time (hours)

What does kWh mean for electric cars?

An electric car battery’s kWh (kilowatt-hour) refers to its energy capacity. It indicates how much energy the battery can store and deliver to power the vehicle.

1- Battery Capacity (kWh)

A battery rated 60 kWh can supply 60 kilowatts for 1 hour, or 30 kilowatts for 2 hours, etc. Larger capacities, like 100 kWh, generally translate to longer driving ranges.

2- Driving Range

The battery’s kWh capacity directly impacts how far an EV can travel on a charge. Range depends on the vehicle’s efficiency, usually measured in kWh per mile.

For example:

If a car uses 0.25 kWh per mile, a 60 kWh battery would provide:

0.25kWh/mile60kWh=240miles

3- Charging

When charging an electric car, the energy added to the battery is also measured in kWh.

4- Power vs. Energy

- kW (kilowatt): Measures the power (how fast energy is used or delivered).

- kWh (kilowatt-hour): Measures the total energy stored or consumed over time.

Why Battery Cost Per kWh Matters?

The cost of a battery accounts for 20–30% of an EV’s total cost; therefore, lower kWh prices significantly influence the vehicle’s affordability.

Here’s how the kWh prices of EV batteries have implications for both buyers and the automotive industry at large:

1. Cheaper EVs for Buyers

Lower battery prices enable manufacturers to produce more affordable EVs.

2. Longer Ranges Without Price Spikes

Lower battery prices enable manufacturers to set their prices lower than their competitors while extending the range of their vehicles.

3. Faster Adoption of Electric Trucks and SUVs

The reduced price of bigger battery packs allows for the rapid expansion of electric trucks and SUVs, a growing market segment.

The Magic Number: $100 Per kWh

It marks an important milestone that everyone keenly observes: $100 per kWh. Analysts forecast that when this marker is reached, EVs will be within reach for many buyers, just like traditional gas-powered cars. We’re getting close to achieving that target. CATL and BYD are already selling LFP packs at the $100 per kWh rate.

What’s Driving the Price Drop?

Some key reasons are collectively working towards the reduction of the cost of batteries:

1. Economies of Scale

Firms such as CATL and LG manufacture millions of cells annually, enabling them to reduce costs through cyclical production.

2. Better Technology

Emerging battery technologies like solid-state and lithium-sulfur promise to use cheaper materials and achieve higher performance, though mass rollout is expected in late 2020s or early 2030s.

3. Recycling

Advancements in battery recycling from firms like Redwood Materials recover about 80–90% of lithium, nickel, and cobalt from used batteries, reducing raw material costs.

4. Government Incentives

Incentives like tax credits and grants in the U.S. and Europe (e.g., the Inflation Reduction Act) support domestic battery production and lower consumer costs.

Regional Differences in Battery Costs

Battery costs also vary based on the region:

China has the cheapest battery costs of any country, paying approximately $100 to $115 per kWh, thanks to inexpensive labor and government support.

The U.S. and Europe: These regions have slightly higher battery costs, ranging from $130 to $160 per kWh, mainly due to their newer supply chains and regulations.

How Does Battery Cost Affect You?

As battery prices continue to fall, their impact is felt by EV buyers and manufacturers alike:

Electric Trucks: Over time, electric trucks like the Ford F-150 Lightning and the Rivian R1T will become more accessible to a broader audience as large battery packs, which are greater than 1 kWh, become cheaper.

New EVs: Battery prices are expected to fall starting in 2023, making a basic sedan now $30,000 attainable for the average Person.

Used EVs: The decreasing prices of batteries make old batteries cheaper to replace, which increases the resale value of used EVs.

The Future of Electric Car Battery Cost Per kWh

Looking forward, the price of EV batteries is set to continue its decline:

- 2025: Average pack costs are expected to hit $100/kWh.

- 2030: With the adoption of solid-state technology, prices could fall further to $80/kWh.

- By 2040, breakthroughs in sodium-ion and lithium-air technologies could reduce battery costs to as low as $50/kWh.

| Year | Estimated Battery Cost per kWh |

|---|---|

| 2025 | Approximately $100 |

| 2030 | $70–$80 with the adoption of solid-state technologies |

| 2040 | $40–$50 with breakthroughs in sodium-ion and lithium-air batteries |

Final Thoughts

Electric vehicles will become economically competitive with traditional petrol cars when the cost reaches $100 per kWh.

The shift from NMC to batteries will influence the price and performance of EVs.

Recycling and local production of batteries will make electric vehicles (EVs) even more cost-effective and efficient in the future.